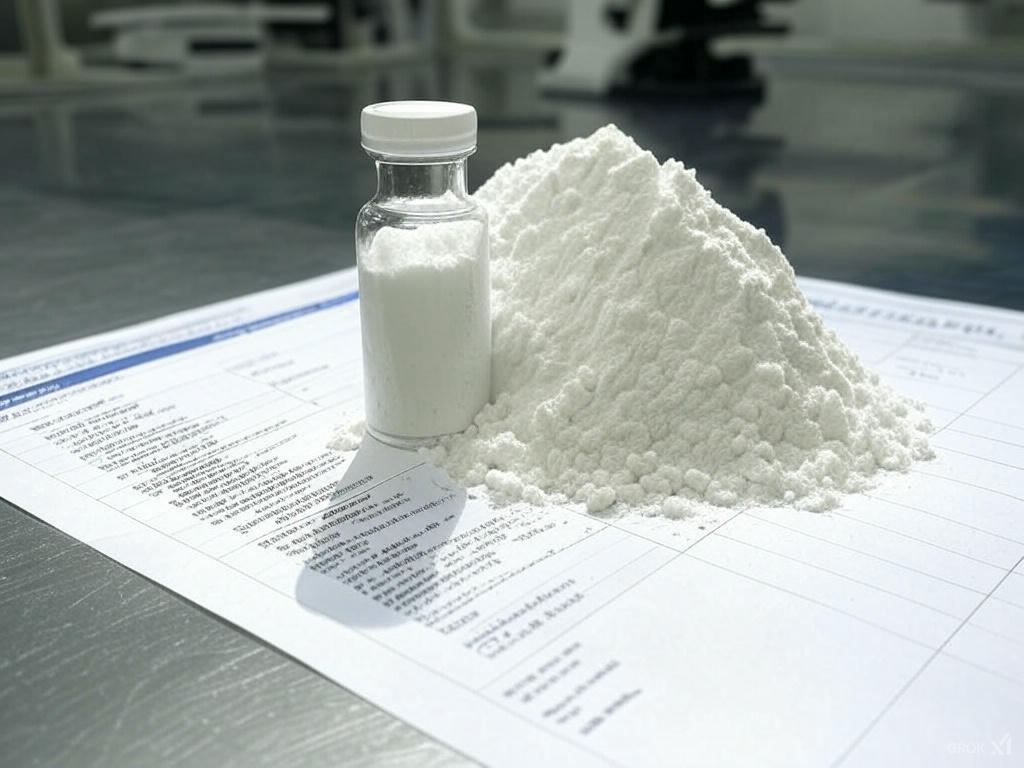

Product Name: Hydroxypropyl Methyl Cellulose Acetate Succinate (HPMCAS)

CAS Number: 71138-97-1

Date: March 01, 2025

General Description

Hydroxypropyl Methyl Cellulose Acetate Succinate (HPMCAS) is a white to off-white, free-flowing powder derived from hydroxypropyl methylcellulose (HPMC) by esterification with acetic and succinic anhydrides. It is a pH-sensitive, amorphous polymer used primarily as an enteric coating material and solubility enhancer for poorly soluble drugs in pharmaceuticals. HPMCAS is insoluble in acidic environments (e.g., stomach pH) but dissolves in neutral to slightly alkaline conditions (e.g., intestinal pH), with solubility tailored by grade.

Typical Applications

- Pharmaceuticals: Enteric coatings for tablets and pellets, solid dispersions for bioavailability enhancement

- Nutraceuticals: Protective coating for acid-sensitive compounds

- Drug Delivery: Amorphous solid dispersions (ASDs) via hot-melt extrusion or spray drying

- Research: pH-dependent release systems

Technical Specifications

| Property | Value |

| Appearance | White to off-white powder |

| Methoxyl Content | 20.0–24.0% (w/w) |

| Hydroxypropoxyl Content | 5.0–9.0% (w/w) |

| Acetyl Content | 5.0–14.0% (w/w) (varies by grade) |

| Succinoyl Content | 4.0–18.0% (w/w) (varies by grade) |

| Moisture Content | ≤ 5.0% |

| Ash Content | ≤ 0.5% |

| Bulk Density | 200–400 g/L |

| Particle Size | 95% passes through 100 mesh |

| Viscosity | 2.4–3.6 cP (10% in acetone, varies by grade) |

| pH (1% dispersion) | 4.0–6.0 |

| Solubility | Insoluble in water (pH < 5.5–6.0); soluble in acetone, ethanol, and pH > 5.5–7.0 aqueous media |

| Loss on drying (%) | ≤5.0 |

| Residue on ignition (%) | ≤0.20 |

| Heavy metals (ppm) | ≤10 |

| Content | LG | MG | HG |

| Acetyl group | 5.0-9.0 | 7-11 | 10-14 |

| Butyl two acyl group | 14-18 | 10-14 | 4-8 |

Performance Properties

- Enteric Properties: Dissolution pH varies by grade (e.g., L-grade: pH > 5.5; M-grade: pH > 6.0; H-grade: pH > 6.8), protecting drugs in gastric conditions.

- Solubility Enhancement: Increases bioavailability of poorly soluble drugs via amorphous solid dispersions.

- Film Formation: Forms flexible, transparent films resistant to acidic environments; excellent compatibility with plasticizers (e.g., triethyl citrate).

- Thermal Stability: Suitable for hot-melt extrusion (Tg ~120–135°C); decomposes above 150–160°C.

- Stability: Stable in dry form; protects active ingredients from moisture and acid degradation.

Storage and Handling

- Storage Conditions: Store in a cool, dry place (5–30°C) in tightly sealed containers, away from moisture and heat sources.

- Shelf Life: Minimum 24–36 months under proper storage conditions.

- Packaging: 25 kg multi-layer paper bags or fiber drums with polyethylene lining.

Safety Information

- Non-hazardous under normal handling conditions.

- Avoid dust inhalation; use protective equipment (mask, gloves) during handling.

- Consult the Safety Data Sheet (SDS) for detailed safety and disposal instructions.

Usage Guidelines

- Coating Application: Dissolve in organic solvents (e.g., acetone/ethanol 50:50) at 5–10% concentration with plasticizers (e.g., 10–20% TEC) for spray coating.

- Solid Dispersion: Process via hot-melt extrusion (HME) at 120–150°C or spray drying with drug at 1:1 to 1:4 polymer:drug ratio.

- Typical Dosage:

- Enteric coating: 5–15% of tablet weight

- ASDs: 20–80% of formulation weight

- Processing: Use fluid-bed or pan coaters for coatings; ensure adequate drying to prevent tackiness.

Notes

- Grades: Common grades (e.g., L, M, H) differ in acetyl/succinoyl ratios and dissolution pH:

- L-grade: Lower succinoyl, dissolves at pH > 5.5

- M-grade: Medium succinoyl, dissolves at pH > 6.0

- H-grade: Higher succinoyl, dissolves at pH > 6.8

- Regulatory: Included in USP/NF, EP, and FDA Inactive Ingredients Database for oral solid dosage forms.

- Higher acetyl content improves organic solubility; higher succinoyl content raises dissolution pH.